From Drawing to Layout

Upload CAD files and get optimized lines, aisles, and utilities in minutes.

From concept to factory floor, NeoFab AI transforms designs into optimized layouts that power faster, smarter manufacturing.

NeoFabAI is an end-to-end software solution for modern manufacturers looking to scale quickly and efficiently. Founded by three entrepreneurs with backgrounds in engineering, AI and management, NeoFabAI represents a revolution in manufacturing planning and execution.

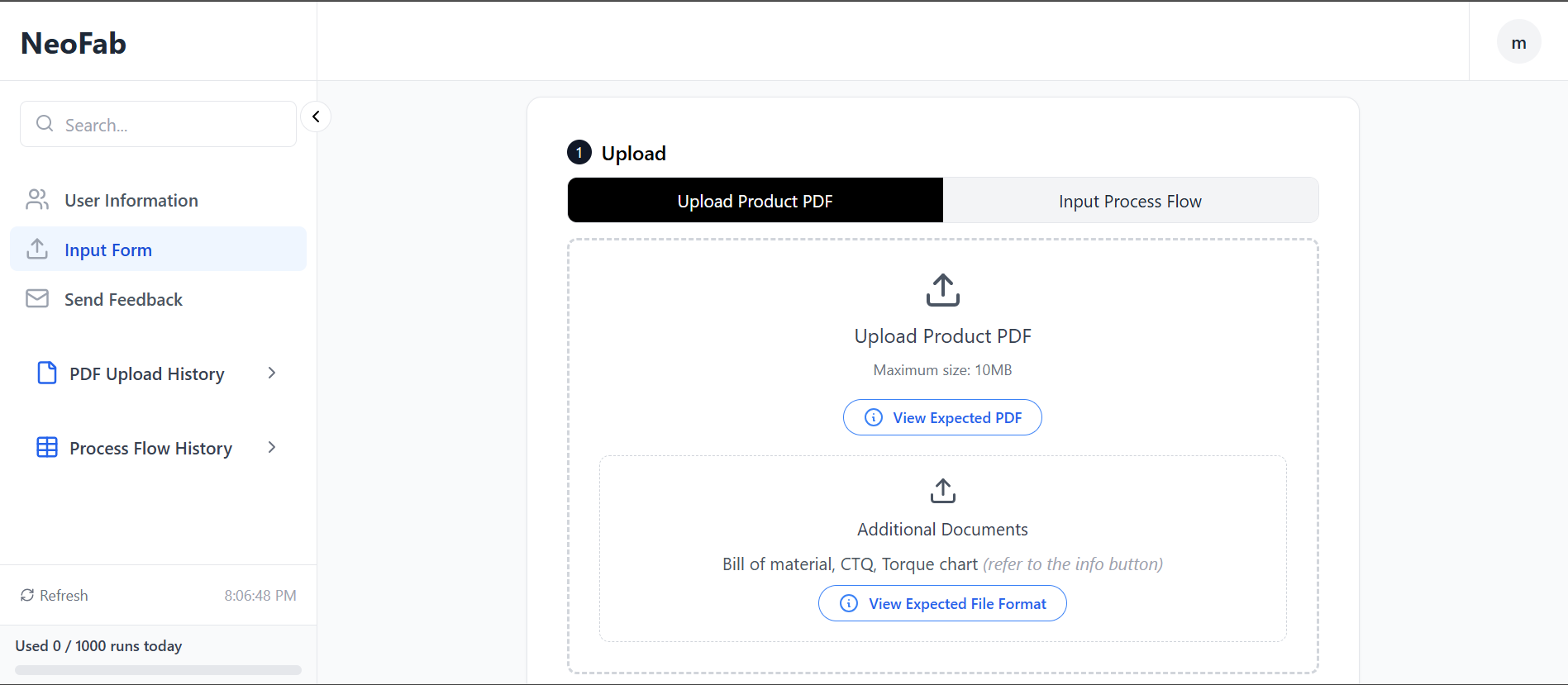

Our platform allows companies to upload their designs and drawings to instantly generate full-scale factory layouts and detailed execution plans. This innovation reduces the time and cost of scaling production, making it a game-changer for startups and established manufacturers alike.

What sets NeoFabAI apart is its comprehensive approach - we support manufacturers from start to finish with plans, suppliers, layouts and even become the Manufacturing Execution System (MES) once the factory is operational, creating a continuous improvement cycle.

What a team of 5 would take 4 weeks to accomplish, NeoFabAI can deliver in just 30 minutes - with higher precision and greater detail.

Three moments that collapse months of planning into minutes.

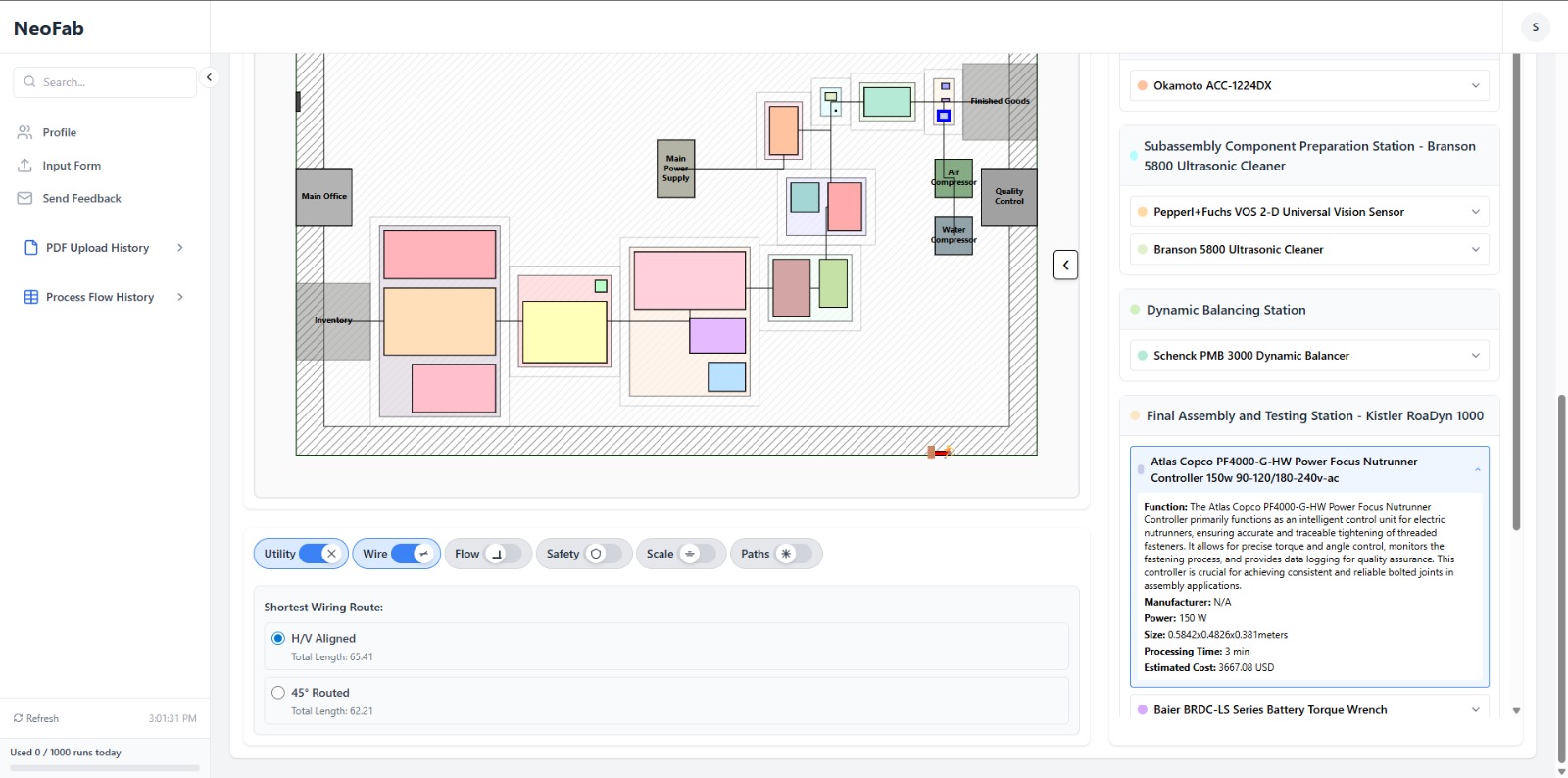

Upload CAD files and get optimized lines, aisles, and utilities in minutes.

Turn specs into vetted suppliers. RFQs go from weeks to a single day.

Export layouts, compliance packs, and push tasks into project management.

Upload your specs and constraints to generate production-ready layouts with aisles, utilities, and safety built in.

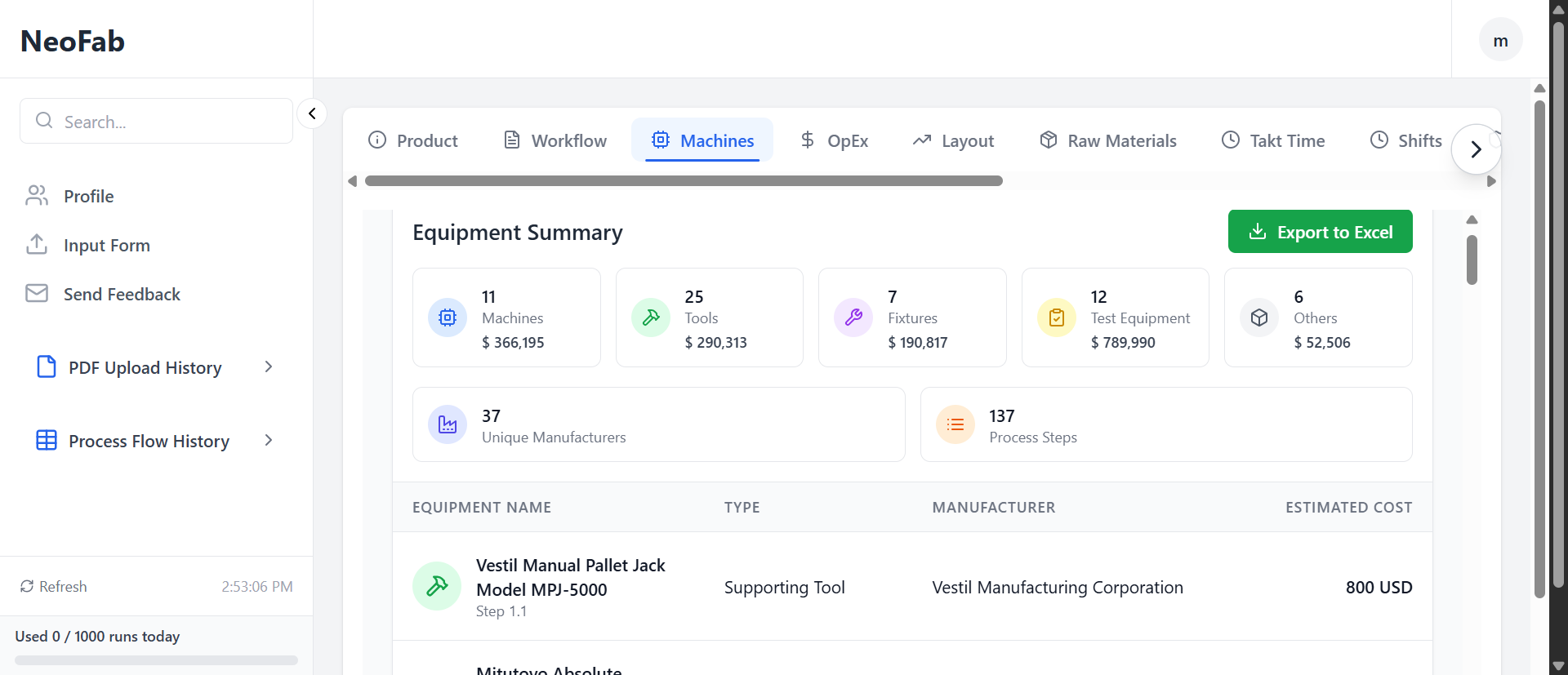

AI maps process steps and machine options for takt, throughput, and yield — no spreadsheets, no guesswork.

Go from specs to qualified suppliers in one flow. RFQs cut from weeks to a single day.

Instant CapEx/OpEx insights with trade-off comparisons for smarter decisions.

Built-in standards and AI checks keep throughput high without sacrificing yield.

Replace fragmented sheets with a unified vendor view for faster, integrated supply chains.

Layouts are based on CAD inputs, OEM datasheets, and verified supplier data. Every output is traceable and benchmarked against industry standards.

Yes. Upload your current layouts or machine lists, and NeoFab will suggest workflow improvements, utilization boosts, and alternate configurations.

Factory setups that normally take 12–18 months can be completed in 3–6 months. Layout generation drops from weeks to under an hour.

NeoFab is industry-agnostic and works across electronics, batteries, automotive, and other manufacturing verticals.

By automating planning, vendor selection, and layout optimization, companies cut setup costs by up to 50%.

Join teams using NeoFab to scale production with confidence. No more scattered PDFs or guesswork.